-

High-accuracy clamping improves final part quality

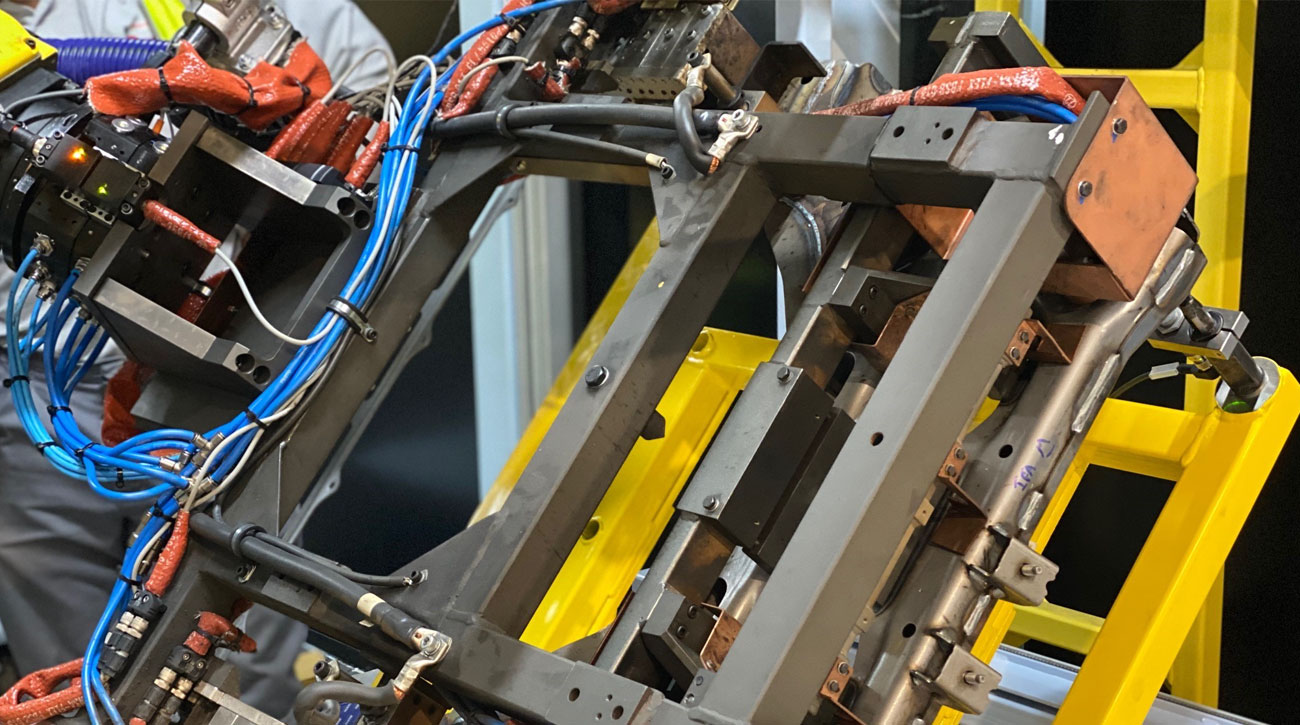

Nissan Motor Manufacturing UK (NMUK) boosts suspension welding precision and accessibility by standardising KOSMEK’s SWP Expansion Locating Pin Clamps across all jig-less welding cells.

The largest Nissan plant in Europe, producing over 350,000 cars annually including the Qashqai, Juke, and the all-electric Leaf.

In 2021, NMUK introduced jig-less welding cells for Qashqai front and rear suspension manufacturing. The new process demanded:

NMUK selected KOSMEK SWP Expansion Locating Pin Clamps for their:

The success of the first installations led NMUK to standardise SWP clamps in all jig-less welding applications. Multiple repeat orders followed, including for two new production lines dedicated to electric vehicle suspension components launching in 2025/2026.