-

Reduces mould change time

Faster and safer clamping of vertical moulds, with consistent repeatability on the shop floor.

From glasses and contact lenses to asthma inhalers, insulin pens and blood diagnostic devices. Our work can be found in products where extreme precision is vital. We believe that constantly pushing the envelope and delivering work of the highest possible quality is the key to making people all over the world healthier and happier.

IGS GeboJagema sought a safer and easier way to clamp moulds on its vertical injection moulding machines, aiming to enhance operator safety, streamline setup procedures, and achieve a higher level of precision and repeatability in daily operations.

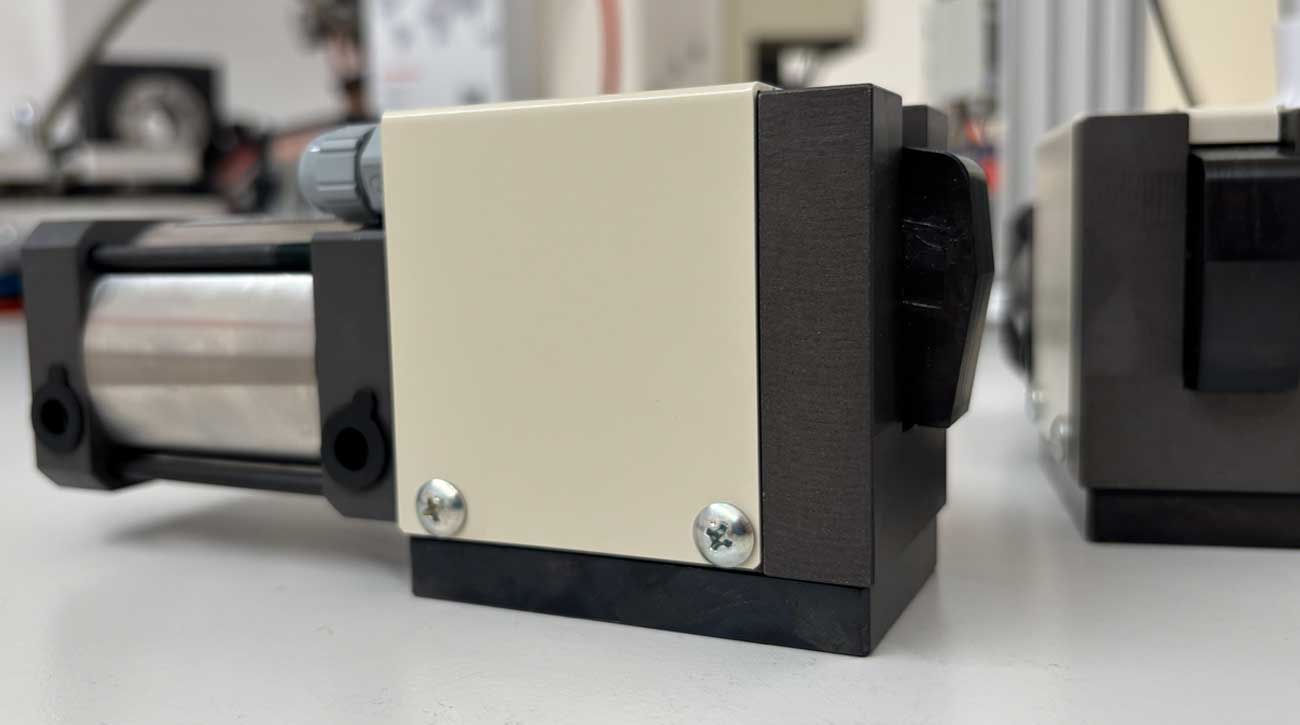

The introduction of KOSMEK HC clamps has provided a safer, faster, and more user-friendly clamping solution for our moulds, delivering significant improvements across both our vertical and horizontal injection moulding machines.

IGS GeboJagema saves approximately 15 minutes with every mould change, boosting efficiency across our production line.

A dedicated electrical safety signal now provides an extra layer of protection on the injection moulding machine, ensuring enhanced operational safety.