-

No impact from casting deviations

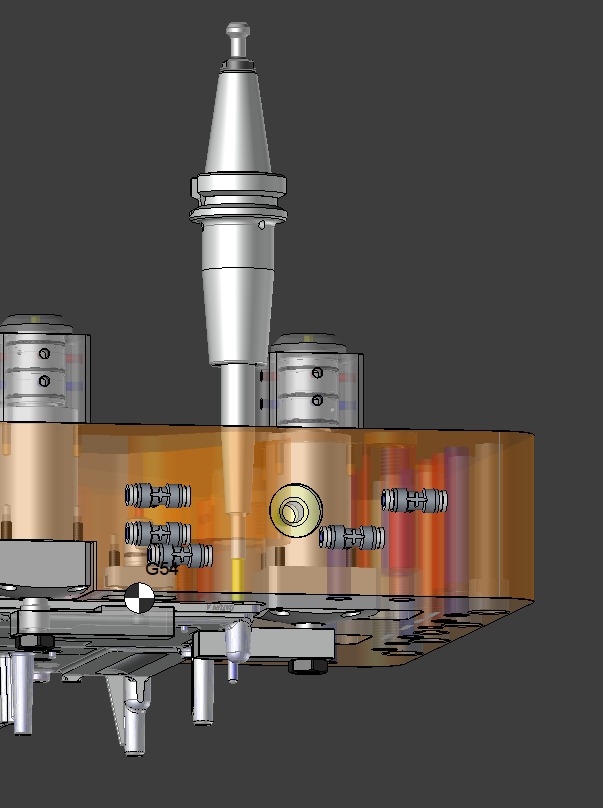

Single-setup machining for a high-volume electromobility HPDC component with repeatable location despite casting variation.

Vioral SA is an aluminium high pressure die casting company with a strong automotive focus, operating with a clear emphasis on automation, process discipline, and international customer programs.

For a new high-runner electromobility component, Vioral faced a double challenge:

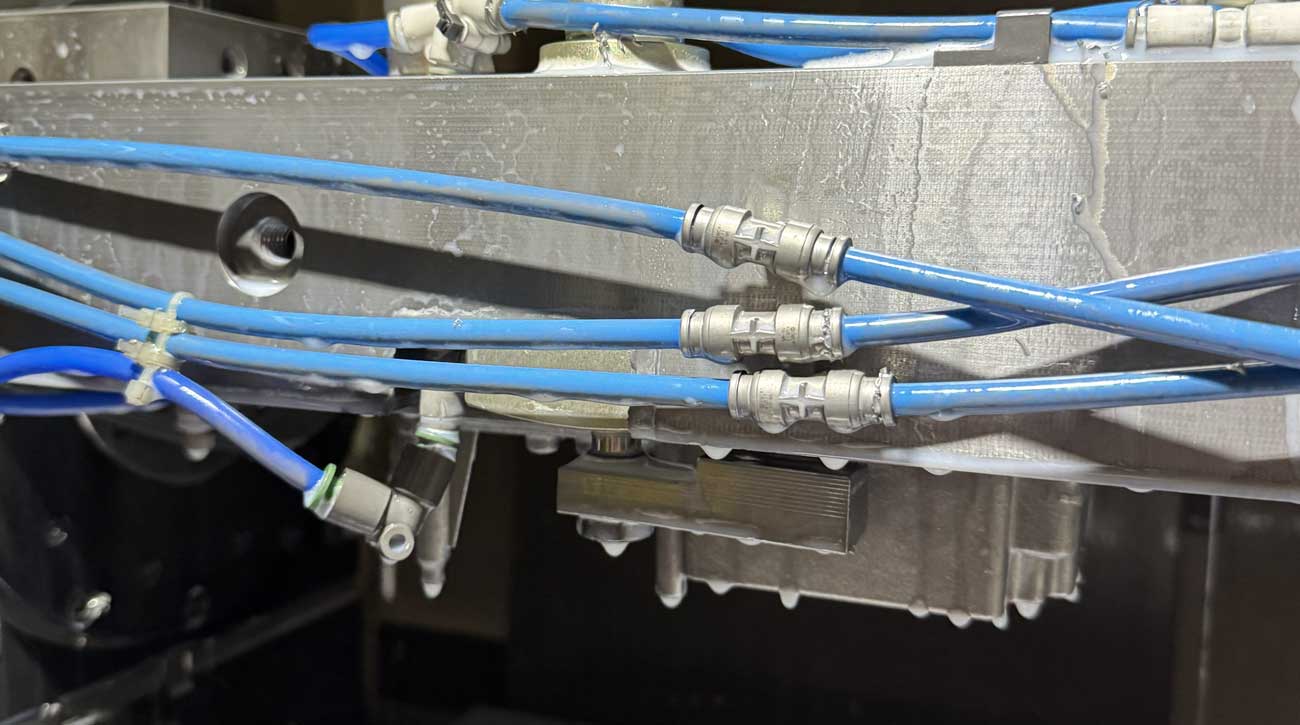

Vioral integrated KOSMEK components directly into the fixture design to solve both requirements:

30% lower investment in CNC machines for the project, enabled by machining the part in a single setup.