-

Fast, repeatable pallet clamping in under 10 minutes

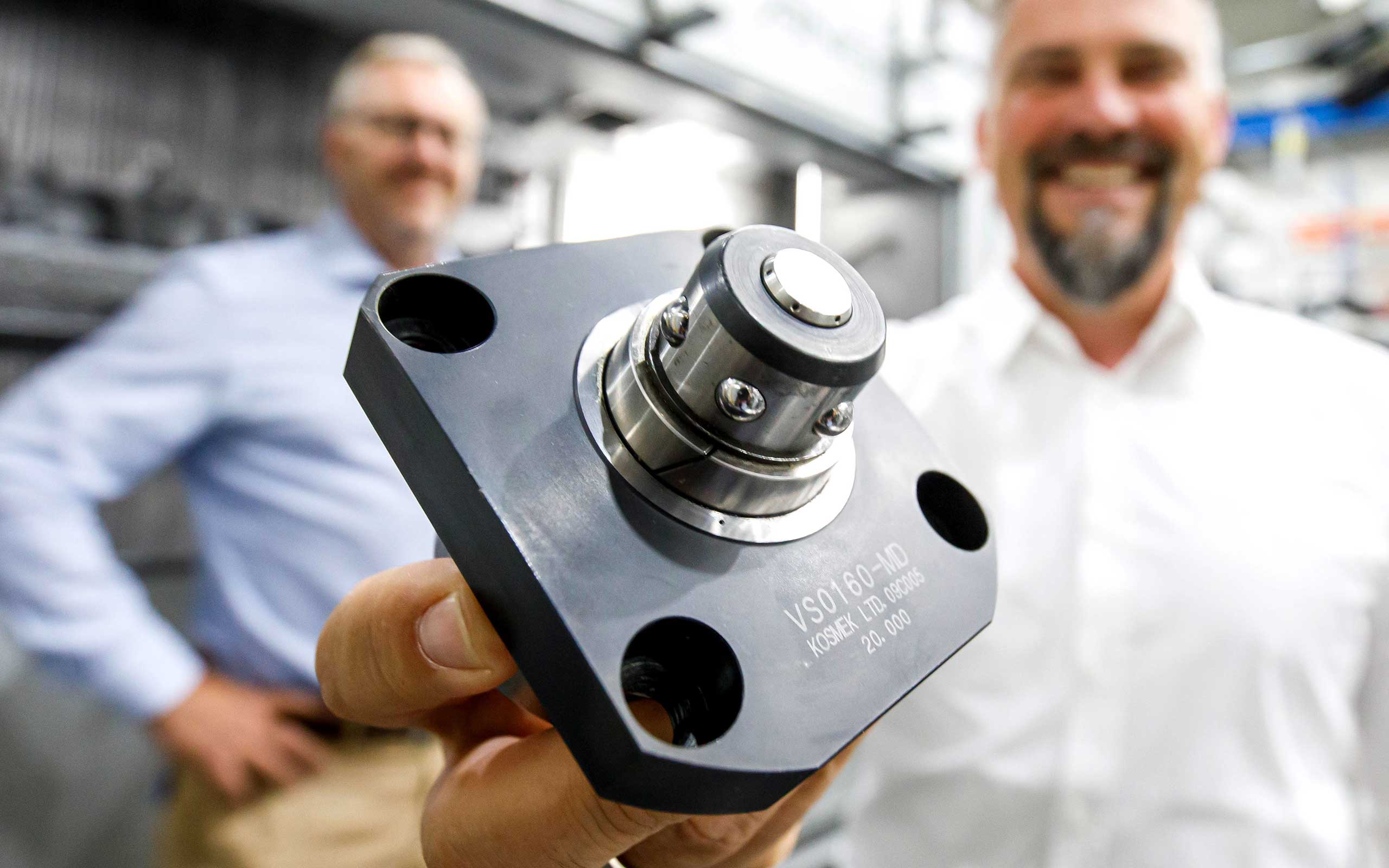

ANGER Machining boosts productivity and shortens setup times in high‑volume structural part production with KOSMEK’s VS Pallet Clamp, achieving 3 µm repeat accuracy.

Austrian machine builder providing high-precision machining centers for e-mobility structural components.

ANGER needed to minimize setup times while machining thin‑walled, vibration‑sensitive structural parts and battery trays for OEMs such as Daimler, Volkswagen or Stellantis, without compromising accuracy or stability.

KOSMEK’s VS Pallet Clamp, a patented hydraulic zero point clamping system, enabled high speed, high accuracy pallet clamping with 3 µm repeatability. The solution eliminates manual alignment, speeds up changeovers and ensures long term precision even under heavy production loads.

Setup time reduced to under 10 minutes for retooling battery trays; 3 µm repeat accuracy sustained over 1 million cycles.

Improved system uptime, higher process reliability and reduced total cost of ownership.